Waste tire pyrolysis oil is a fuel oil obtained through the thermal decomposition of waste tires under anaerobic or anoxic conditions. The following is some introduction about it:

Components:

Hydrocarbon Compound:75~85%;

Sulphide:0.5~3%;

Nitrogen Compound:0.1~1%;

Metal Impurity:0.01~0.1%;

Polycyclic Aromatic Hydrocarbons:1~5%;

Water + Carbon Black:1~3%;

Composition CharacteristicsFraction composition: It is a complex mixture with a wide boiling range. The light fraction (fraction with a boiling point below 200°C) accounts for more than 20%, the medium fraction (fraction with a boiling point between 200 - 350°C) accounts for about 40%, and the content of the light and medium fractions of the pyrolysis oil accounts for more than 60% of the pyrolysis oil.

Chemical composition: The content of unsaturated hydrocarbons is very high, and it shows a decreasing trend with the increase of the boiling point of the fraction. The content of aromatic hydrocarbons in each narrow fraction, except for the fraction with a boiling point above 500°C, is between 60% - 70%. The content of asphaltenes in each narrow fraction oil is very low, and only the content of asphaltenes in the fraction with a boiling point above 500°C is very high. In the fraction with a boiling point below 500°C, with the increase of the boiling point of the fraction, the contents of total sulfur and thiophene sulfur show an increasing trend. Mercaptan sulfur is mainly concentrated in the fraction oil with a boiling point below 300°C, and sulfide is mainly concentrated in the fractions with a boiling point below 150°C and above 500°C. Sulfur mainly exists in the form of thiophene sulfur. With the increase of the boiling point of the fraction, the content of basic nitrogen in the pyrolysis oil shows an increasing trend. In the fraction with a boiling point below 500°C, the contents of total nitrogen and non-basic nitrogen also show an increasing trend. Basic nitrogen accounts for about one-third of the total nitrogen, and non-basic nitrogen accounts for two-thirds of the total nitrogen. The acid value of the pyrolysis oil shows a trend of first increasing and then decreasing with the increase of the boiling point of the fraction, and acidic substances are mainly concentrated in the fraction with a boiling point between 200 - 400°C.

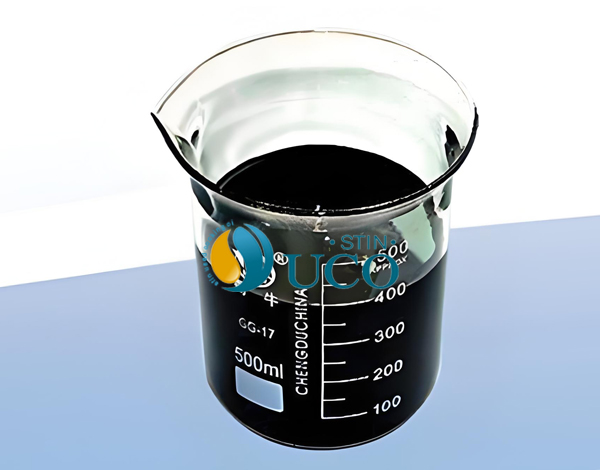

Physical properties: It is a dark-colored, turbid, and high-density liquid with a strong odor. The density is 950 - 970 kg/m³, the flash point is relatively low, less than 32°C, and the calorific value is 40 - 43 MJ/kg.

Application FieldsHeating industry: It can be used as a fuel for heating boilers in the heating industry and can be applied to various heavy industry factories, such as steel plants, cement plants, boiler plants, heavy oil power plants, etc. Compared with traditional fuels, waste tire pyrolysis oil has a high calorific value, low sulfur content, and low cost. It can meet the emission standards after the boiler is heated and save operating costs.

Chemical industry: It can be used as a raw material in the chemical industry. For example, when processing and producing organic acids, fatty acids, and other chemical products, waste tire pyrolysis oil can be used as a fuel to accelerate the chemical process and can also be used to produce products such as solvents and lubricants.

Power generation industry: It can be used as a power generation fuel and can also be used as a component of certain fuel cells.

Regional heating system: It can be used in the regional heating system to centrally provide heat for multiple buildings or the entire community. It can be distributed through a pipeline network to provide heat for space heating and domestic hot water.

Transportation field: Through further refining treatment, waste tire pyrolysis oil can be converted into non-standard diesel and used for diesel generators, trucks, ships, mining machinery, etc. In addition, some companies are trying to process it into sustainable aviation fuel to support the transformation of the aviation industry to sustainable fuels.